Home / Manufacturing

Ensuring Drug Packaging Quality & Safety

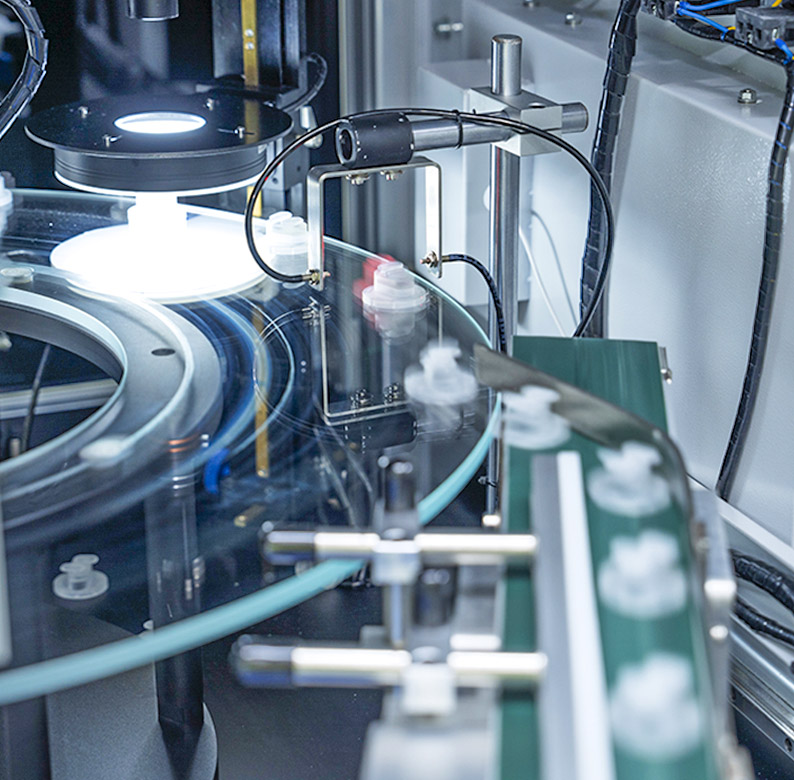

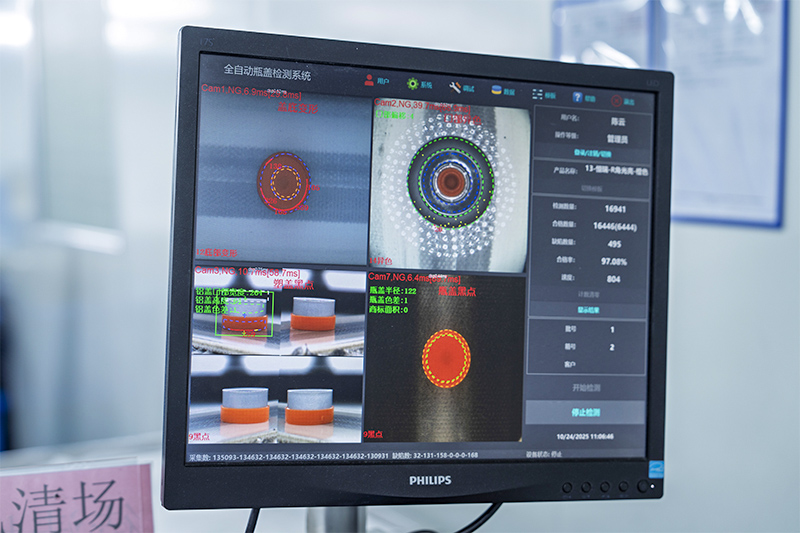

Jiangsu Changjiang Lids Co., Ltd. strictly guarantees product quality and safety through industry-leading production processes.Products are produced in advanced cleanroom that complies with GMP regulations. Changjiang Lids has an experienced technical team advanced automated production lines, online camera detection systems, and professional cleaning processes, which ensures that products meet strict quality requirements and provides reliable performance.

Delivering Reliable Pharmaceutical Packaging

Jiangsu Changjiang Lids Co., Ltd., specializing in sealing materials for primary pharmaceutical packaging with a focus on Aluminum-Plastic Caps and Euro PP Caps, is committed to precision and reliability. Our advanced production system meets strict global pharmaceutical regulations, ensuring products are safe, pure, and stable.

Our factory adopts a modern cleanroom concept, equipped with fully automated production lines, intelligent visual inspection systems, and validated surface treatment processes.

The manufacturing system is founded on strict quality systems and efficient processes. Its capabilities encompass the entire line of precision products—from standard designs to custom solutions—engineered for exceptional performance.

Our factory adopts a modern cleanroom concept, equipped with fully automated production lines, intelligent visual inspection systems, and validated surface treatment processes.

The manufacturing system is founded on strict quality systems and efficient processes. Its capabilities encompass the entire line of precision products—from standard designs to custom solutions—engineered for exceptional performance.

High Quality & Innovation

For safer drugs, stronger trust and more efficient supply chains.

-

Controlled environment

The production area is strictly designed to prevent cross contamination, equipped with air locks, transfer type cleaning equipment, and independent process areas to ensure optimal cleanliness. -

Process integrity

Our automated production and high-performance ultrasonic cleaning systems minimize manual intervention, governed throughout by strict personnel and operational controls. This integrated command over equipment, procedures, and personnel ensures consistently reliable, compliant output, defining our commitment to true process integrity. -

Comprehensive monitoring

An automated monitoring system checks for surface quality issues on plastic cap, including but not limited to color variation, black spots, and surface roughness, guaranteeing compliance with strict quality and industry specifications. -

Defect prevention and control

Each aluminum-plastic cap undergoes validated visual inspection to verify surface quality and dimensional accuracy. A dedicated control system is in place to prevent and eliminate potential foreign objects.

English

English