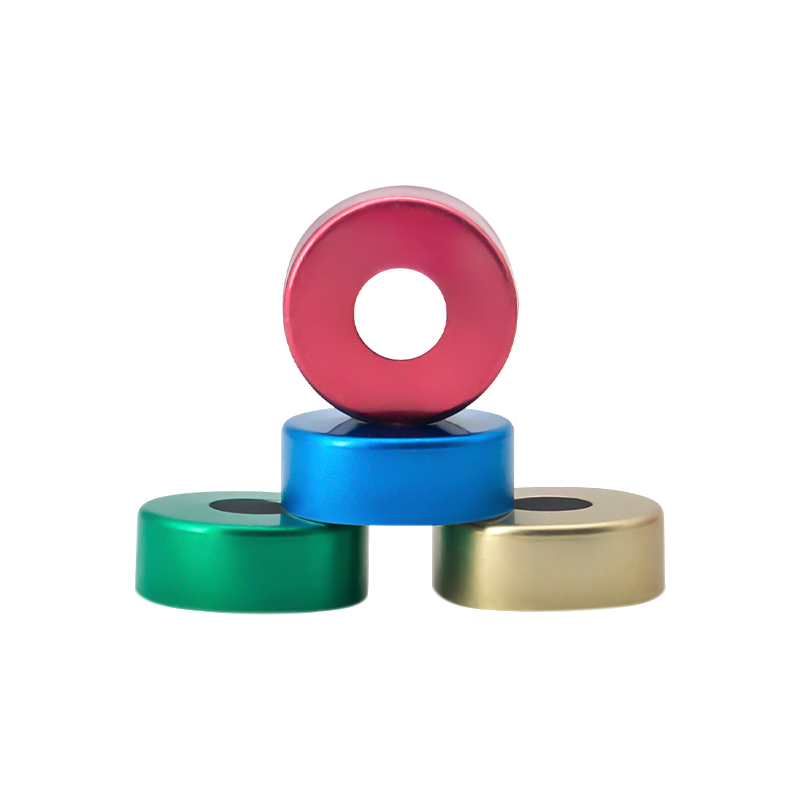

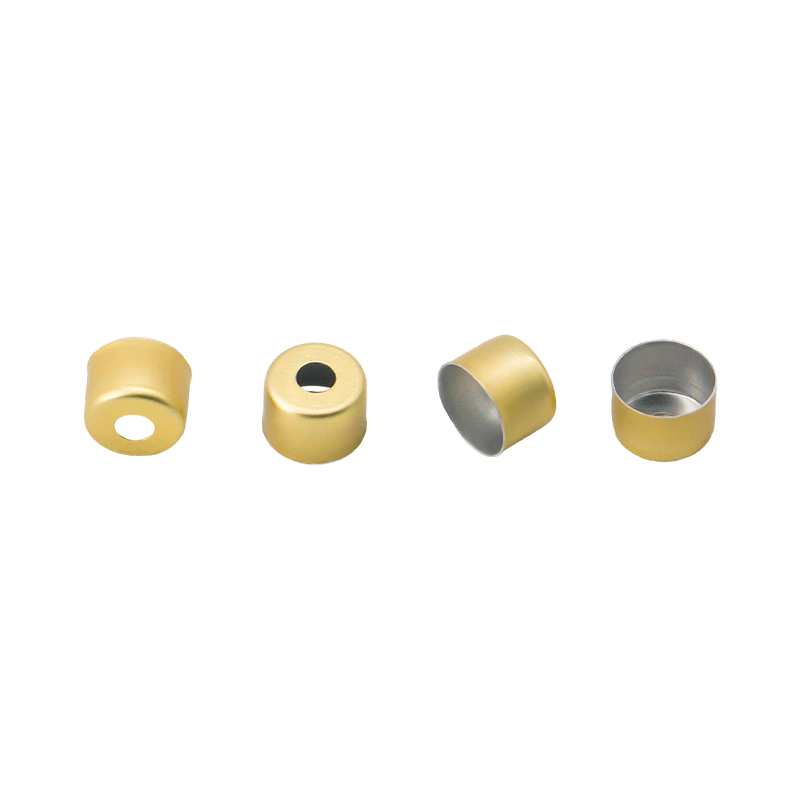

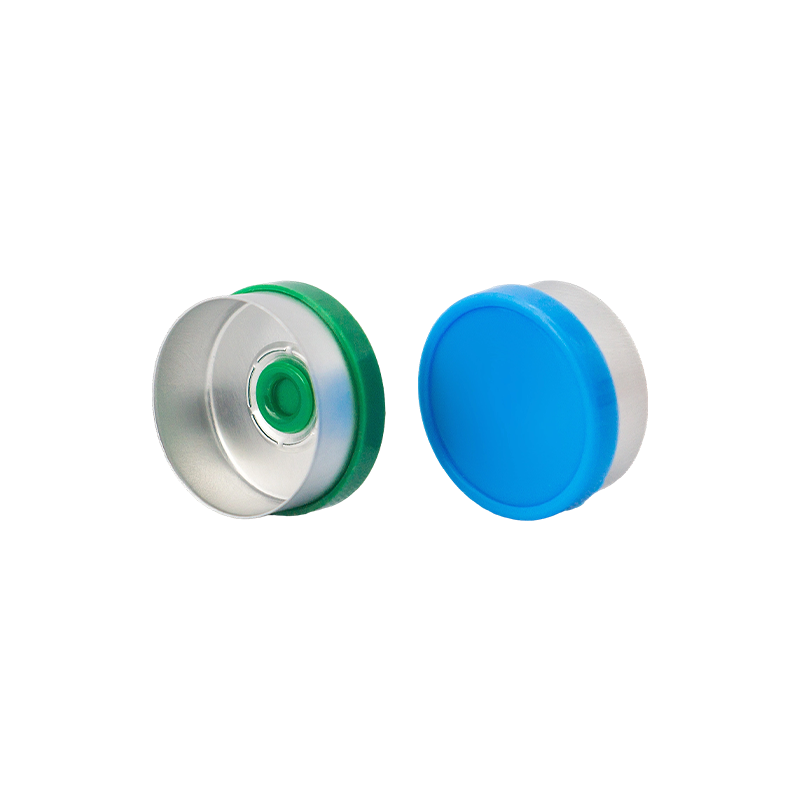

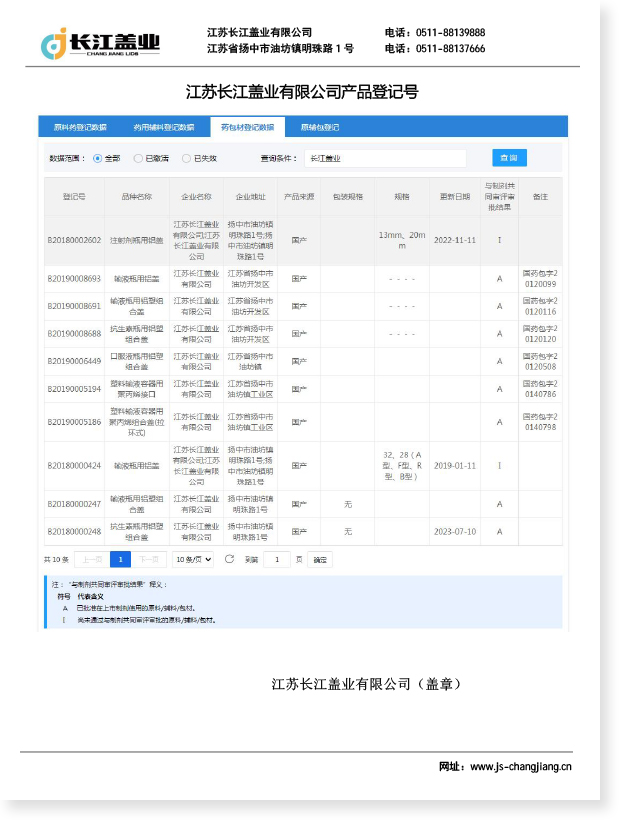

We mainly produce various types of primary pharmaceutical packaging products, including vaccine vial caps, antibiotic vial caps, injection vial caps, oral liquid bottle caps, infusion bottle caps, polypropylene caps for infusion containers, plastic hangers for infusion bottles, and contact lens cases, delivering reliable high-quality protection for all types of medications. The workshop is equipped with advanced production equipment and laboratory testing instruments, achieving a foundational level of automated production. The annual production capacity of aluminum and aluminum-plastic caps reaches 3 billion, while polypropylene caps can reach 800 million.

We follow the GMP regulations of the pharmaceutical industry and ISO 9001 quality system requirements. It has designed and built C+A level cleanroom to provide cilents with higher-quality, environmentally friendly, and value-driven products. Over the years, we have continuously researched, developed, and cultivated a professional technical team to earn global recognition for its clean packaging solutions.

Upholding the quality principle of “Crafted for Precision, Dedicated to Health”, we integrate GMP and ISO 9001 into its quality system. Product quality control spans the entire production process to serve our clients better.

English

English